For more information send us a request: info@realspa.it | +39 0775 1564073

Follow us on social media:

DISCOVER OUR RANGE

The Attritor Mill Range

INFO & CONTACTS

REGISTERED OFFICE

Via XV Strada, 28 ZIP 95121 Catania (CT)

REGISTERED OFFICE

Via XV Strada, 28 ZIP 95121 Catania (CT)

RealSpa offers advanced and customized solutions for waste treatment, with a focus on innovation and sustainability

OPERATIONAL HEADQUARTERS

Via Armando Vona, 8 ZIP 03100 FROSINONE (FR)

+39 0775 1564073

The Attritor Mills represent technological excellence and are designed to ensure high performance and optimal efficiency in industrial refining processes.

Subscribe to our Newsletter

Stay updated on all the news about our services and the sector in which we operate

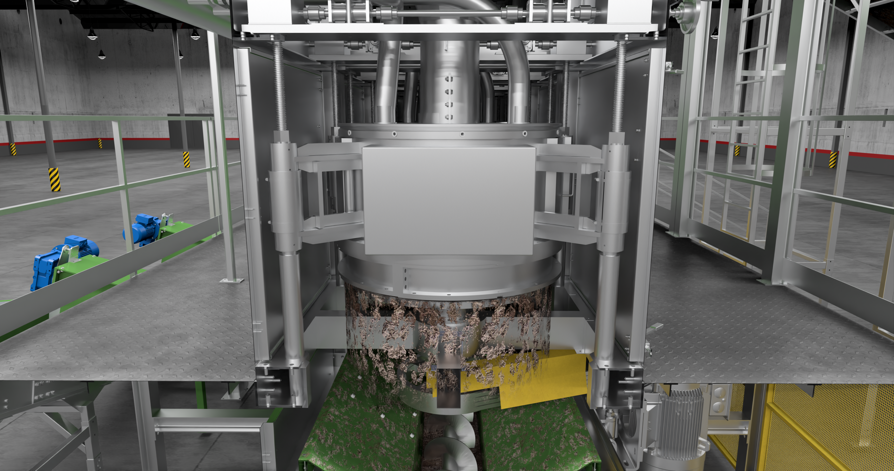

The heart of Attritor Mill is represented by the refining chambers.

The particular conditions to which the waste is subjected result in numerous advantages, including size reduction, loss of the aqueous component, reduction of the time required for material stabilization, and reduction of odorous emissions.

RealSpa S.r.l. | VAT: 05779790871

RealSpa S.r.l. | VAT: 05779790871

@ All Right Reserved 2025 - Website created by Flazio Experience

Main advantages

Production of CSS-C

Sanitization

Size reduction

Volume reduction

FOP

UNI CEN 15359

From 2mm to 15mm

From 50% to 60%

Reduction of biostabilization times

Processing capacity

Weight reduction

Reduction of biodigestion times

From 12 to 16 m3/h

From 30% to 55%

Energy consumption

Leachate reduction

Emission reduction

Reduction of operating costs

From 36 to 38 kWh/m

Attritor Mill

Organic Pro

It is Real Spa's solution for refining the undersieve fraction of unsorted waste. Specifically designed for the treatment of waste with high humidity, rich in organic fraction and mixed polymers, thanks to its unique features, it speeds up the biostabilization process. Installed upstream of a traditional MBT plant, Attritor Mill Organic Pro allows the reduction of IRDP below the limit values of 1000mg O₂ kg⁻¹ h⁻¹ after about 7-10 days (240 hours).

Attritor Mill

CSS-C Pro

It represents the most advanced technology on the market for the production of Secondary Solid Fuel (CSS-C) from the refining of the residual fraction of unsorted waste. With Attritor Mill Css-C Pro, waste becomes a resource that can be used in cement factories and waste-to-energy plants, helping to reduce costs and providing a more sustainable solution compared to fossil fuels. The end-of-waste CSS-C produced with Attritor Mill CSS-C Pro is homogeneous in size and calorific value and is characterized by a low moisture content.

Attritor Mill

Biodigester Pro

Particularly suitable for the treatment of waste with high humidity and rich in organic fraction and mixed polymers, the Attritor Mill Biodigester Pro can be integrated for the recovery of plastic waste resulting from the pressing process. The mechanical-chemical actions that develop in the refining chambers cause the immediate expulsion of liquids and gases and the micronization of the waste particles. This results in a substantial reduction in humidity and, consequently, in weight and in the transformation of the waste into RDF.

The Attritor Mill system complies with the requirements specified in the "Industry 4.0 Model"

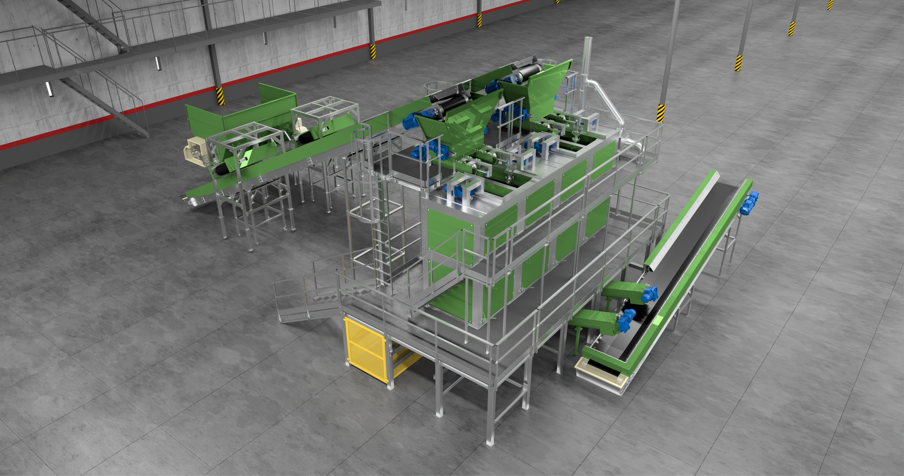

The Attritor Mill system consists of one or more independent processing jars (which can be operated individually) that can be integrated to meet the process requirements of each operator.