For more information send us a request: info@realspa.it | +39 0775 1564073

Follow us on social media:

DISCOVER OUR RANGE

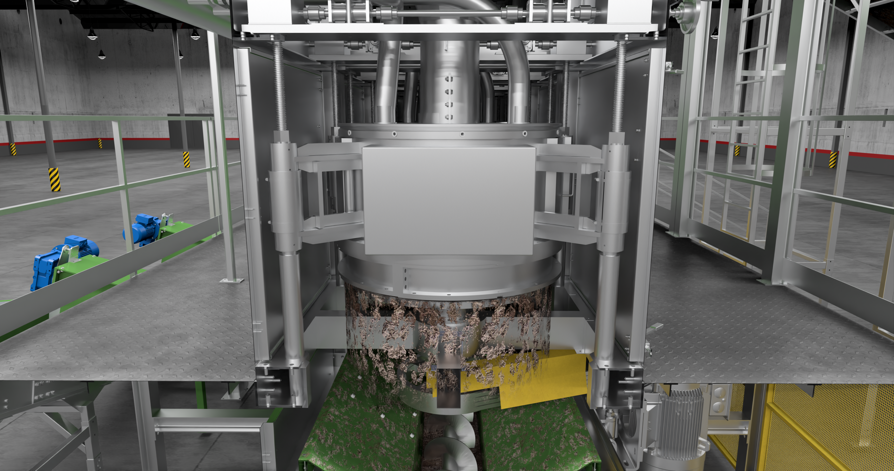

Attritor Mill Biodigester Pro

INFO & CONTACTS

REGISTERED OFFICE

Via XV Strada, 28 ZIP 95121 Catania (CT)

REGISTERED OFFICE

Via XV Strada, 28 ZIP 95121 Catania (CT)

RealSpa offers advanced and customized solutions for waste treatment, with a focus on innovation and sustainability

OPERATIONAL HEADQUARTERS

Via Armando Vona, 8 ZIP 03100 FROSINONE (FR)

+39 0775 1564073

The components of the Attritor Mill Biodigester Pro plant are particularly suitable for the treatment of waste, with very high humidity and rich in organic fraction and mixed plastic polymers.

Subscribe to our Newsletter

Stay updated on all the news about our services and the sector in which we operate

Attritor Mill Biodigester Pro features a unique hybrid technology that combines an attritor with different spheres and blades operating at high speeds.

RealSpa S.r.l. | VAT: 05779790871

RealSpa S.r.l. | VAT: 05779790871

@ All Right Reserved 2025 - Website created by Flazio Experience

The mechanical-chemical process that develops inside the Attritor Mill jars not only leads to the size reduction of the waste components but also to a significant reduction in weight and volume.

The Attritor Mill Biodigester Pro can be integrated for the valorization of plastic waste resulting from the pressing process.

In fact, the plastic fraction, derived from the pressing of the organic fraction, after being subjected to centrifugation, is sent to the refining chambers of the Attritor Mill Biodigester Pro where the mechanical-chemical actions to which it is subjected result in the immediate expulsion of liquids and gases and the size reduction of the materials. This results in a substantial reduction in moisture and, consequently, weight.

The waste, thus treated, is transformed into CSS-C.

Furthermore, the puree resulting from the pressing can be sent to the biodigester.

ALL THE ADVANTAGES

The combination of installing the Attritor Mill micronizer and designing an optimized plant layout allows customers to significantly reduce company costs.

All this is reflected in RealSpa's focus on continuous innovation, research, and development of increasingly efficient and economically convenient solutions in terms of technologies for waste recovery.

01.

02.

03.

Reduction of the degree of complexity of organic compounds

Increase in the activity of methanogenic bacteria

Reduction of volatile fatty acids

through the elimination of volatile organic compounds during the treatment phase.

less time required to perform hydrolysis.

thanks to the extremely high impact pressure.

04.

05.

06.

Reduction of mesophilic load

High quality CSS

CSS End of Waste < 5mm

originating through the exponential increase in temperature.

produce secondary solid fuel with higher calorific value.

allows obtaining recognition of CSS as a useful material, compliant with environmental regulations, reducing environmental impact and promoting the reuse of waste

07.

08.

09.

Improved homogeneity

Waste reduction

Reduction of volume and weight

increases energy efficiency in combustion.

transforms waste into sources of energy, reducing dependence on landfills.

High-energy grinding reduces the volume of materials by up to 60%, and results in a loss of about 55% of the weight.

Layout Attritor Biodigester Pro

Overlap

Recovery of 20% of the organic fraction

Centrifuge

Biodigester

Ferrous Separation

Ferrous

Metals

Metals

Non-ferrous

Screening

Volume -60%

Weight -55%

CSS - C

GET TO KNOW OUR REALITY

The Attritor Mill system complies with the requirements specified in the "Industry 4.0 Model"

The Attritor Mill system consists of one or more independent processing jars (which can be operated individually) that can be integrated to meet the process requirements of each operator.