For more information send us a request: info@realspa.it | +39 0775 1564073

Follow us on social media:

WHAT WE DO

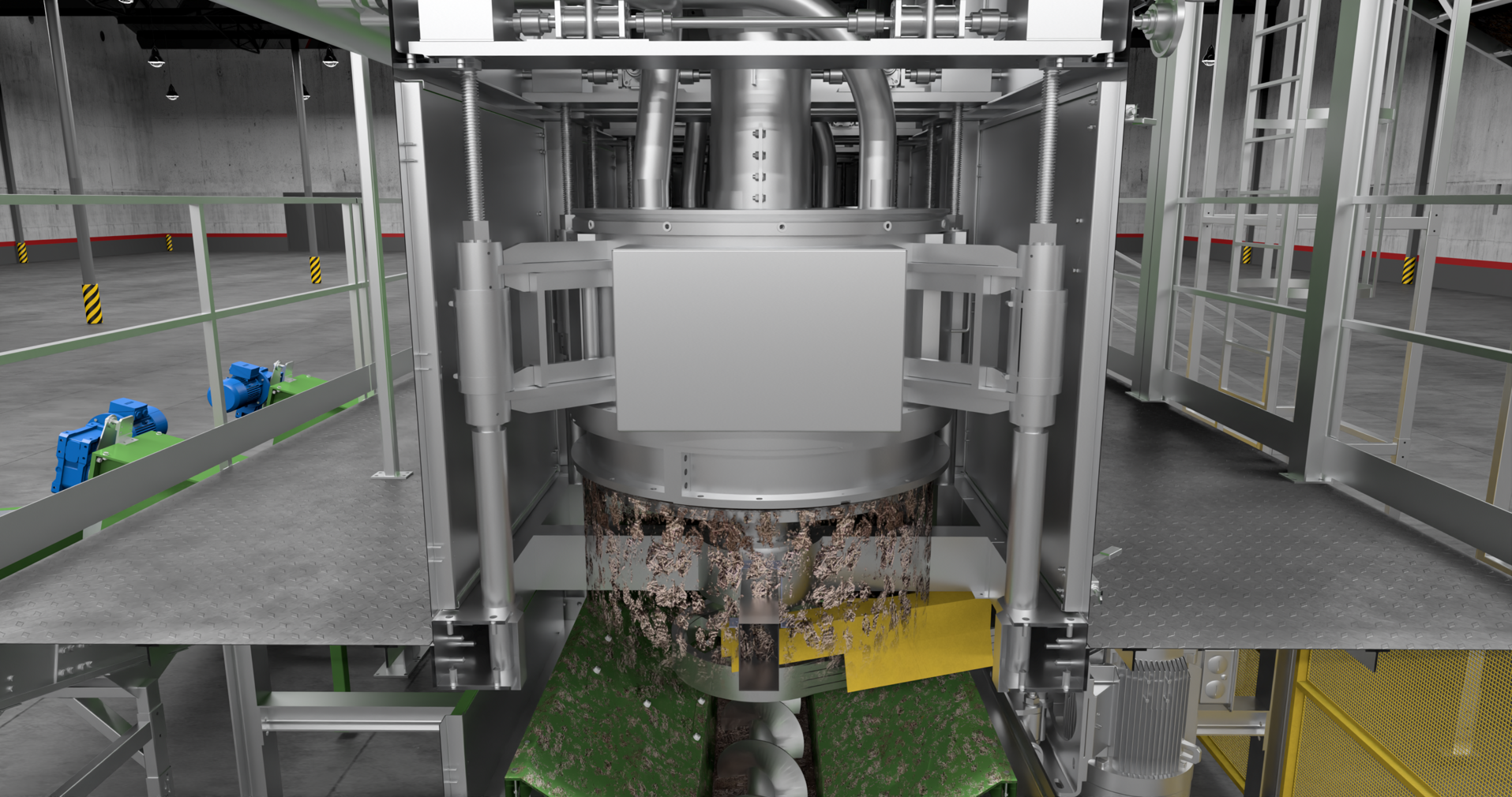

RealSpa offers advanced and customized solutions for waste treatment, with a focus on innovation and sustainability.

Design

Service

Support and Spare Parts

RealSpa provides a comprehensive after-sales service, ensuring continuous support for its Attritor Mill systems.

RealSpa offers a production and supply service for spare parts for Attritor Mill systems, guaranteeing optimal performance and system longevity.

RealSpa offers a personalized design service, where each project is tailored to meet the specific needs of the client.

INFO & CONTACTS

REGISTERED OFFICE

Via XV Strada, 28 ZIP 95121 Catania (CT)

REGISTERED OFFICE

Via XV Strada, 28 ZIP 95121 Catania (CT)

RealSpa offers advanced and customized solutions for waste treatment, with a focus on innovation and sustainability

OPERATIONAL HEADQUARTERS

Via Armando Vona, 8 ZIP 03100 FROSINONE (FR)

+39 0775 1564073

Subscribe to our Newsletter

Stay updated on all the news about our services and the sector in which we operate

Our services range from custom plant design, to the optimization of industrial processes, to maintenance and post-sales technical support

RealSpa S.r.l. | VAT: 05779790871

RealSpa S.r.l. | VAT: 05779790871

@ All Right Reserved 2025 - Website created by Flazio Experience

Design

RealSpa offers a personalized design service, where each project is tailored to meet the specific needs of the client.

RealSpa engineers work closely with clients to analyze the characteristics of the facility and optimize workflow, space management, and operational efficiency. Careful and meticulous design ensures that each facility is configured to maximize productivity, reduce operating costs, and comply with environmental and safety regulations.

ALL THE ADVANTAGES

The combination of installing the Attritor Mill micronizer and designing an optimized plant layout allows customers to significantly reduce company costs.

All this is reflected in RealSpa's focus on continuous innovation, research, and development of increasingly efficient and cost-effective solutions in waste valorization technologies.

Odor reduction

Efficiency

Reduction of the spirometric index

drastically accelerates biostabilization, improving composting and biogas production.

The micronization process helps to reduce bad odors, making the treatment more environmentally friendly and acceptable.

improves air quality during treatment, reducing the release of fine dust.

Reduction of volume and weight

Sustainability

Saving

High-energy grinding reduces the volume of organic materials by up to 50% with a simultaneous reduction of about 30% in weight.

optimizes the transformation of organic waste into usable products, promoting the circular economy.

considerable reduction in energy consumption is around 36 KW/t.

Service

RealSpa provides a comprehensive after-sales service, ensuring continuous support for its Attritor Mill systems.

The Full Service offered by RealSpa is designed to support customers at every stage of the plant's life cycle, from design to installation, up to the daily management of the plant. This service includes technical assistance to resolve operational issues, staff training for optimal use of the plant, and both routine and extraordinary maintenance interventions.

After-sales support is essential to maintain high performance and extend the useful life of the plant. In fact, the scheduled and timely maintenance service helps prevent problems that could compromise the plant's efficiency, improving its overall reliability and minimizing downtime.

Production and supply of spare parts

RealSpa offers a service of production and supply of spare parts for Attritor Mill systems, guaranteeing optimal performance and system longevity.

RealSpa engineers work closely with clients to analyze the characteristics of the plant and optimize workflow, space management, and operational efficiency. Careful and meticulous design ensures that each plant is configured to maximize productivity, reduce operating costs, and comply with environmental and safety regulations.

The spare parts supplied are specifically designed to fit the machinery, minimizing downtime and ensuring that the plant always operates at its maximum capacity. RealSpa's technical support team is available to assist customers in choosing the appropriate spare parts, offering effective and personalized solutions. RealSpa's spare parts supply service guarantees continuous and uninterrupted operation, improving plant productivity and customer satisfaction.

REQUEST MORE INFORMATION

Let's talk about your project

Do you need a reliable partner for your next project? Contact us for information, consultations, and quotes.

Our team is at your disposal to offer you the best solutions in the sector.